As global construction evolves to meet stricter environmental regulations and higher performance standards, WPC co-extruded cladding is poised to lead the exterior materials market in 2025. Combining cutting-edge technology with eco-conscious design, this innovative cladding solution addresses the growing demand for resilient, low-maintenance, and visually striking building facades. Here’s why industry experts predict its dominance in the coming year.

1. Sustainability: Meeting 2025’s Green Building Mandates

By 2025, over 70% of new construction projects will prioritize materials with recycled content and carbon-neutral certifications. WPC co-extruded cladding rises to the challenge:

60-80% Recycled Materials: Blends post-industrial wood fibers and recycled plastics, diverting waste from landfills.

2. Climate Resilience: Built for Extreme Weather

With climate change intensifying, 2025’s exteriors demand materials that withstand hurricanes, wildfires, and heavy rainfall. WPC co-extruded cladding excels with:

UV-Resistant Cap Layer: Prevents fading and thermal expansion under intense sunlight.

Moisture-Proof Design: Resists rot, mold, and swelling in humid or coastal environments.

Fire Rating Class B1: Meets stringent fire safety codes for urban and wildfire-prone areas.

3. Cost Efficiency: Reducing Lifetime Expenses

A 2024 Global Construction Report reveals that 45% of contractors now prioritize materials with lower lifecycle costs. WPC co-extruded cladding cuts long-term spending by:

25+ Year Lifespan: Outlasts wood (10-15 years) and rivals PVC (15-20 years).

Zero Maintenance: No painting, sealing, or chemical treatments required.

Insurance Savings: Fire and termite resistance may reduce property insurance premiums.

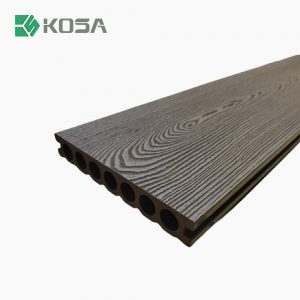

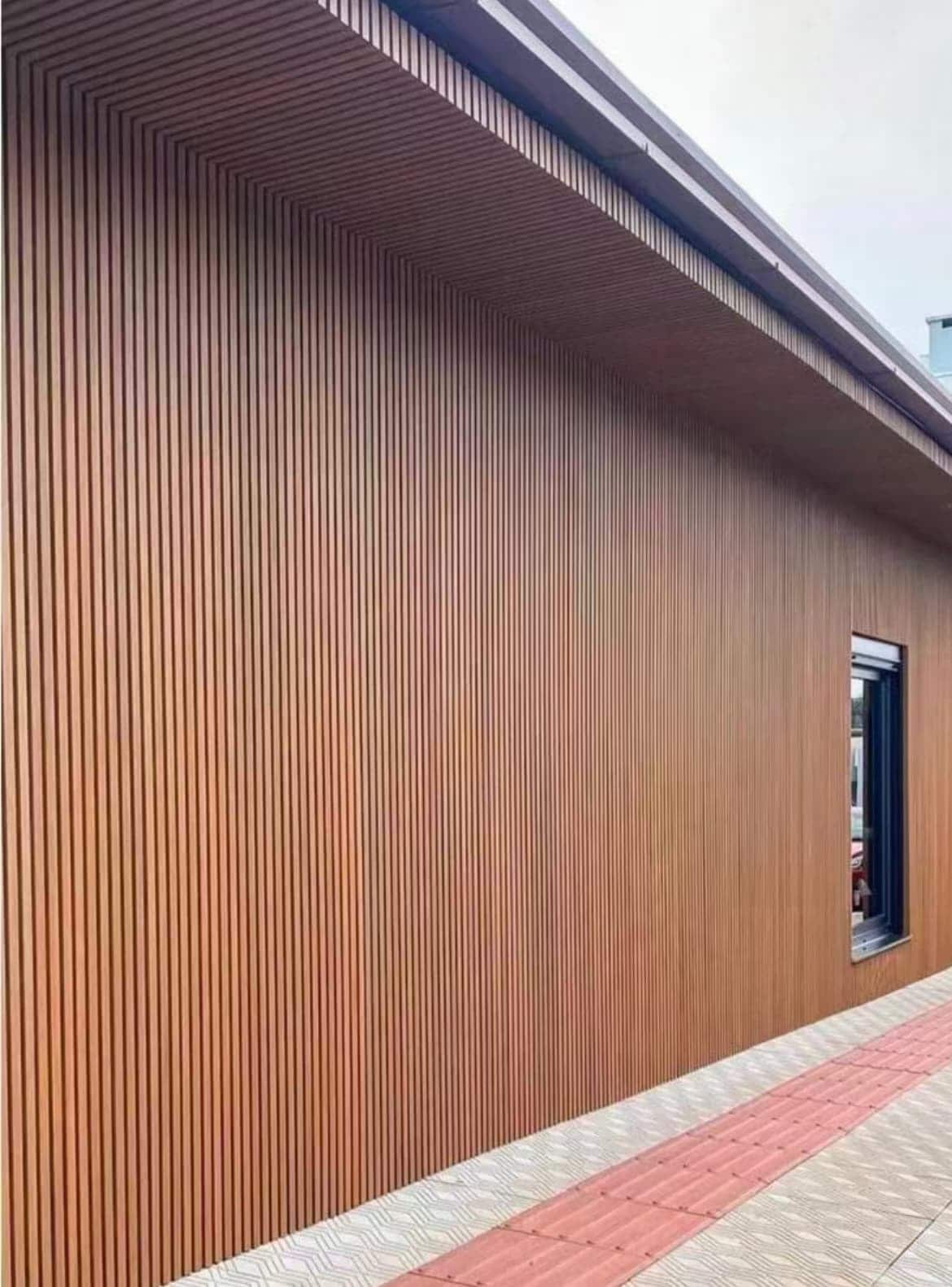

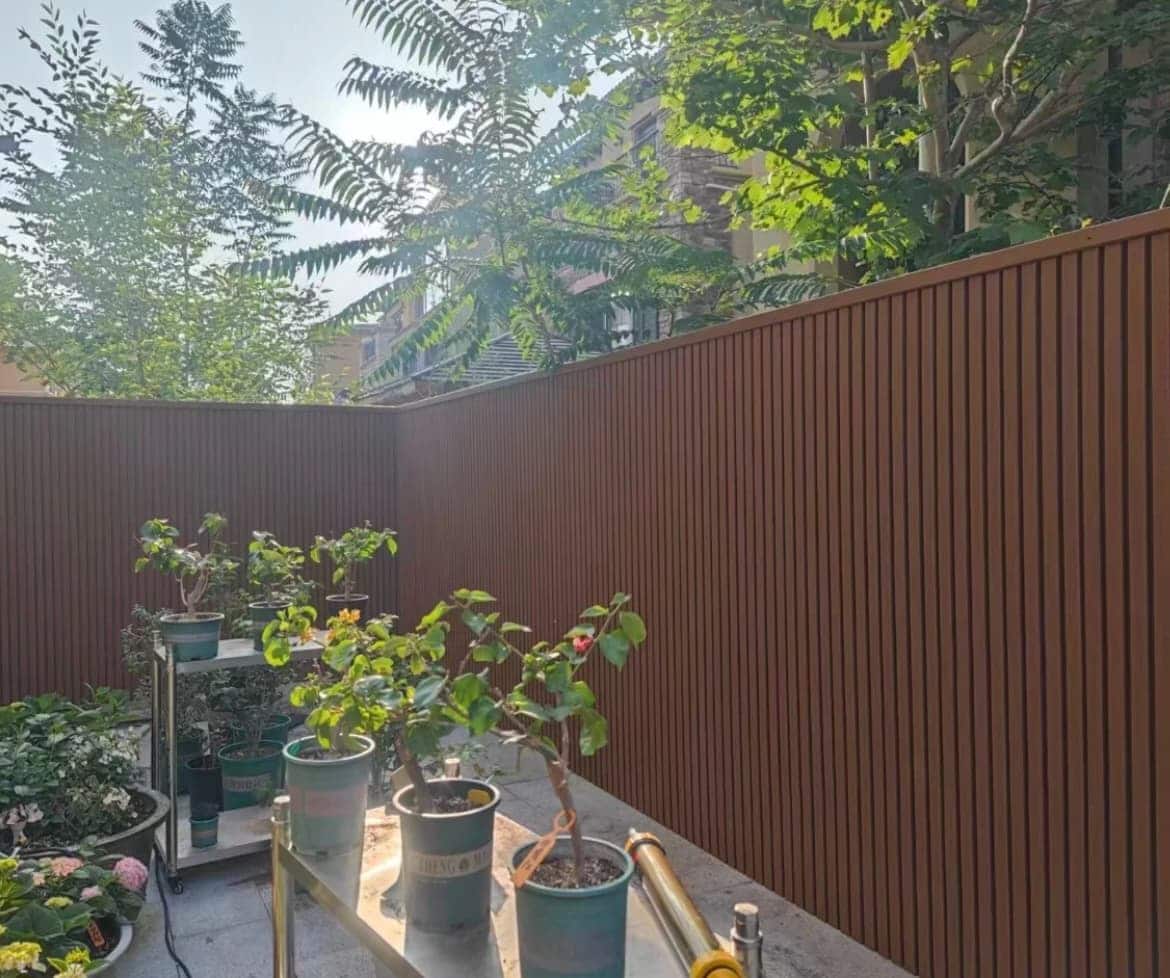

4. Aesthetic Flexibility: Customization for Modern Architecture

Architects in 2025 seek materials that balance aesthetics with functionality. WPC co-extruded cladding delivers:

Realistic Wood Grain Finishes: Mimics teak, cedar, and oak without natural wood’s flaws.

Custom Color Options: From neutral tones to bold hues, adaptable to any design theme.

Seamless Installation: Hidden fastener systems create clean, modern lines for residential and commercial projects.

5. Industry Forecast: Market Growth & Adoption Rates

According to Market Research Future, the global WPC cladding market will grow at a 9.2% CAGR from 2023 to 2030, driven by:

Urbanization: High-rise buildings in cities demand lightweight, durable materials.

Consumer Awareness: Homeowners increasingly value sustainability and ROI.

Government Incentives: Tax breaks for green construction accelerate adoption.

Conclusion:Stay Ahead with WPC Co-Extruded Cladding

2025’s architectural landscape demands materials that innovate, endure, and inspire. WPC co-extruded cladding not only meets these criteria but sets a new benchmark for smart, sustainable building solutions. Whether you’re designing a luxury villa, a commercial complex, or a community housing project, this material ensures your exteriors remain future-proof.