As a new type of composite material, wood-plastic composite products or WPC products, combine the advantages of wood and plastic. In the past few years, the global wood-plastic composite product market has shown steady growth.

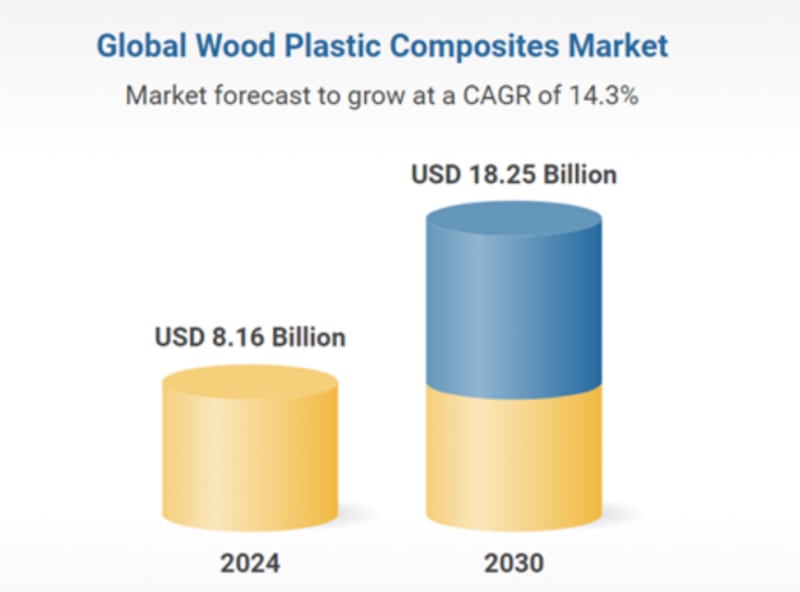

According to statistics , the global wood-plastic composite market has reached US$7.17 billion in 2023, and is expected to reach US$8.16 billion in 2024, with a compound annual growth rate of approximately 14.27%, and reaching USD 18.25 billion by 2030.

In terms of regional distribution, North America and Europe have always been the main consumer markets for wood-plastic composite products. Due to their high emphasis on environmentally friendly materials and mature construction markets, the demand for wood-plastic composite products is relatively strong. However, the market growth in the Asia-Pacific region is the most significant, mainly due to the region’s rapid urbanization, accelerated infrastructure construction, and increasing emphasis on environmentally friendly materials. The growth observed during the historical period can be attributed to several factors, including environmental concerns driving preference for sustainable materials, expansion of the construction industry, increasing preference for low-maintenance materials, emphasis on durability and longevity of construction products, Environmental considerations include reduced reliance on treated wood, and the cost benefits associated with wood-plastic composites.

Environmental Factor

Environmental issues have become a hot topic in today’s society and have received widespread attention around the world, which has greatly promoted people’s preference for sustainable materials. Reliance on treated wood is gradually decreasing due to environmental concerns. Traditionally treated wood may use harmful chemicals during the production process, posing potential threats to the environment and human health. Wood-plastic composite materials replace processed wood to a certain extent and reduce related environmental risks. As an environmentally friendly choice, wood-plastic composite materials have significantly lower environmental impacts during production and use than traditional materials. Its raw materials usually come from recycled plastics and waste wood fibers, which not only reduces the environmental pollution of plastic waste, but also reduces the over-harvesting of virgin wood. The reuse of this resource helps conserve natural resources, protect forest ecosystems, and reduce soil erosion and biodiversity loss caused by felling trees.

During production, wood-plastic composites emit relatively few greenhouse gases and use less energy than many traditional materials. In addition, it does not release harmful volatile organic compounds (VOCs), posing less potential harm to air quality and human health.

From the perspective of product life cycle, wood-plastic composite materials are recyclable. At the end of its service life, it can be put back into production through proper handling and processing, forming a closed cycle, further reducing waste generation and pressure on the environment.

In the production process of traditional treated wood, a large amount of chemicals are often required for anti-corrosion and insect-proof treatment. These chemicals may penetrate into the soil and water sources, causing serious environmental pollution. At the same time, the disposal and burning of wood can also release harmful gases and particulate matter. In contrast, wood-plastic composites replace treated wood to a certain extent, effectively reducing these potential environmental risks.

Looking to the future, as environmental regulations become increasingly stringent and consumers become more environmentally aware, the demand for environmentally friendly materials such as wood-plastic composites is expected to continue to grow. At the same time, technological advancement will also enable wood-plastic composite materials to further reduce their environmental footprint while improving their performance, making greater contributions to achieving sustainable development goals.

Low Maintenance

Consumer demand for low-maintenance materials is growing. In the fast-paced modern life, people expect the materials used to reduce the time and energy investment in daily maintenance. Wood-plastic composite materials happen to have this characteristic. They are not easy to rot, fade and deform, and do not require frequent maintenance and repair.

Cost-effectiveness

Cost-effectiveness is also a big advantage of wood-plastic composite products. Although its initial investment may be relatively high, in the long term, the overall cost is often lower than traditional materials due to its low maintenance costs and long service life.

Development of Construction Industry

The continuous expansion of the construction industry provides a broad application space for wood-plastic composite materials. The large number of new construction projects requires a large amount of building materials, and wood-plastic composite materials have become the new favorite in the construction industry with their unique performance advantages.

In the world of building products, durability and longevity are always important considerations. Wood-plastic composite materials can withstand the test of various harsh environmental conditions, have excellent weather resistance and corrosion resistance, and can still maintain good performance after long-term use.

Performance advantages

Wood-plastic composite products have good weather resistance, corrosion resistance and wear resistance, and can be used in outdoor environments for a long time without frequent maintenance. In addition, they also have the advantages of fire resistance and insect resistance, making them have broad application prospects in construction, garden landscaping and other fields.

The rise of wood-plastic composite materials is the result of a combination of factors. Its future development prospects are exciting and it is expected to continue to lead changes in the field of materials and make greater contributions to sustainable development.