In the era when the architectural field is constantly pursuing innovation and excellence, Co-extrusion Wall Cladding, or Capped Wall Cladding as an emerging architectural decoration material, is gradually emerging with its unique performance and advantages. It not only endows buildings with a beautiful appearance but also demonstrates excellent performance in functionality, durability, and sustainability.

Co-extrusion Wall Cladding is a type of wall panel material manufactured through the Co-extrusion process. This process combines materials with different properties to form a multi-layered sheet, thereby conferring multiple excellent characteristics to the product. First, let’s explore its outstanding performance.

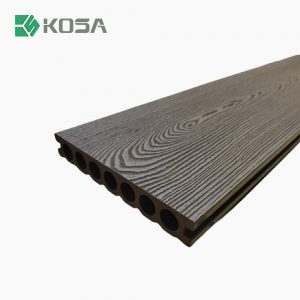

The application of high-performance materials is a major feature of Co-extrusion Wall Cladding. Its core layer typically employs high-strength polymer materials, providing a solid basic structure for the wall panel and ensuring sufficient mechanical strength and stability. The outer layer often uses materials with special properties, such as UV-resistant and weather-resistant materials, enabling the wall panel to be exposed to the outdoor environment for a long time without problems such as fading, cracking, or deformation.

The fire rating is an important consideration index for the safety of building materials. Co-extrusion Wall Cladding performs well in this aspect. By using special fireproof materials and reasonable structural design, it can achieve a high fire rating, providing valuable time for buildings in the event of a fire, reducing the risk of fire spread, and safeguarding the safety of personnel and property.

UV resistance is another highlight of Co-extrusion Wall Cladding. Under direct sunlight, ordinary building materials may gradually age and fade due to UV radiation. However, this co-extruded wall panel is specially treated to effectively resist UV erosion and maintain its bright color and good appearance for a long time.

Corrosion resistance is also one of its non-negligible advantages. Whether in a humid climate or in an environment exposed to chemical substances, Co-extrusion Wall Cladding can maintain stable performance and will not be corroded or damaged. This gives it a significant advantage in applications in harsh environments such as coastal areas and industrial zones.

Today, when sustainable development has become a global consensus, Co-extrusion Wall Cladding also conforms to this trend. The selection of its raw materials tends to be environmentally friendly, the energy consumption during the production process is relatively low, and environmental pollution is reduced. At the same time, after the end of its service life, this wall panel also has a certain recycling value, further reducing the consumption of resources and the pressure on the environment.

The energy-saving effect is another important contribution of Co-extrusion Wall Cladding in sustainable development. It has good heat insulation performance, can effectively reduce the heat exchange between the interior and exterior of the building, reduce the load of air conditioning and heating systems, and thus achieve energy savings.

Customized design is the key for Co-extrusion Wall Cladding to meet the diverse needs of the market. Architects and designers can choose different colors, textures, shapes, and sizes according to the specific style and requirements of the project. This flexibility enables Co-extrusion Wall Cladding to adapt to various building types and showcase unique charm, from modern minimalist commercial buildings to culturally-rich historical buildings.

Easy installation is another advantage of Co-extrusion Wall Cladding. Compared to traditional architectural decoration materials, its installation process is simpler and faster, without the need for complex tools and techniques. This not only shortens the construction period, reduces labor costs, but also reduces possible problems during the construction process.

Cost-effectiveness is an important consideration factor for Co-extrusion Wall Cladding in the market competition. Although its initial investment may be relatively high, considering its long service life, low maintenance costs, and energy-saving effects, the comprehensive cost is often advantageous in the long term. In addition, due to its stable quality, the cost of rework and maintenance caused by material quality problems is reduced, further improving the overall economic benefits of the project.

In practical applications, Co-extrusion Wall Cladding has achieved remarkable results in many fields. In the commercial building sector, such as shopping malls and office buildings, its beautiful appearance and excellent performance can attract more customers and tenants, enhancing the value of the building. In residential buildings, it provides residents with a comfortable and beautiful living environment while increasing the durability and value retention of the house. In industrial buildings, its corrosion resistance and fire resistance can ensure the safe operation of production facilities.

For example, a large shopping mall has adopted Co-extrusion Wall Cladding as the exterior wall decoration material. Its unique color and texture design blend well with the surrounding environment and has become a local landmark building. At the same time, due to its good energy-saving effect, the operating costs of the shopping mall have also been effectively reduced.

However, Co-extrusion Wall Cladding also faces some challenges in the development process. On the one hand, the market’s awareness and acceptance of this new material need to be further improved. Many builders and property owners do not have sufficient understanding of its performance and advantages, resulting in a tendency to prefer traditional products when choosing building materials. On the other hand, the relevant technical standards and specifications are not yet perfect, which to some extent affects its large-scale promotion and application in the market.

To promote the development of Co-extrusion Wall Cladding, all parties in the industry, including Kosa, need to work together. Manufacturers should increase investment in research and development, continuously improve product performance and quality, and reduce production costs. At the same time, strengthen market publicity and promotion to increase consumers’ awareness and trust in the product. The government and industry associations should formulate and improve relevant standards and specifications to provide clear guidance for the application of the product.

Looking to the future, with the continuous advancement of technology and the continuous growth of market demand, Kosa is expected to achieve even more brilliant achievements in the field of Co-extrusion Wall Cladding. Its performance will continue to be optimized, and the application scope will be further expanded, creating a more beautiful, comfortable, and sustainable architectural environment for us.

Co-extrusion Wall Cladding, with its many advantages such as high performance, customization, energy saving, and environmental protection, has become an innovative solution in the field of architectural decoration. Despite some challenges in the development process, with the joint efforts of all parties, it is believed that it will shine more brightly in the future construction market.