Fitting external WPC (Wood Plastic Composite) cladding requires careful planning, appropriate tools, and adherence to manufacturer guidelines. Here’s a step-by-step guide to help you install WPC cladding effectively:

Tools and Materials Required:

-

Tools:

– Drill and screwdriver

– Level

– Measuring tape

– Saw (circular or miter)

– Spirit level

– Rubber mallet

– Chalk line

-

Materials:

– WPC cladding panels

– Starter trims and corner trims

– Fasteners (screws/clips)

– Subframe materials (WPC, aluminum or treated wood battens)

– Weatherproof membrane

Step-by-Step Installation Guide:

-

Prepare the Surface:

– Clean the wall: Remove any debris, dirt, or protrusions from the surface where the cladding will be installed.

– Check for flatness: The wall must be flat to ensure the cladding aligns properly. If it’s uneven, use battens to create a flat sub-frame.

– Apply a weatherproof membrane: Install a breathable waterproof membrane over the wall to protect the structure from moisture.

-

Install the Subframe:

– Use WPC joist, or treated wood battens or aluminum profiles to create a sub-frame. Ensure the sub-frame:

– Has a vertical orientation for horizontal cladding installation, or horizontal orientation for vertical cladding.

– Provides a gap of approximately 30-40cm between battens (depending on manufacturer guidelines).

– Allows for adequate ventilation behind the cladding to prevent moisture buildup.

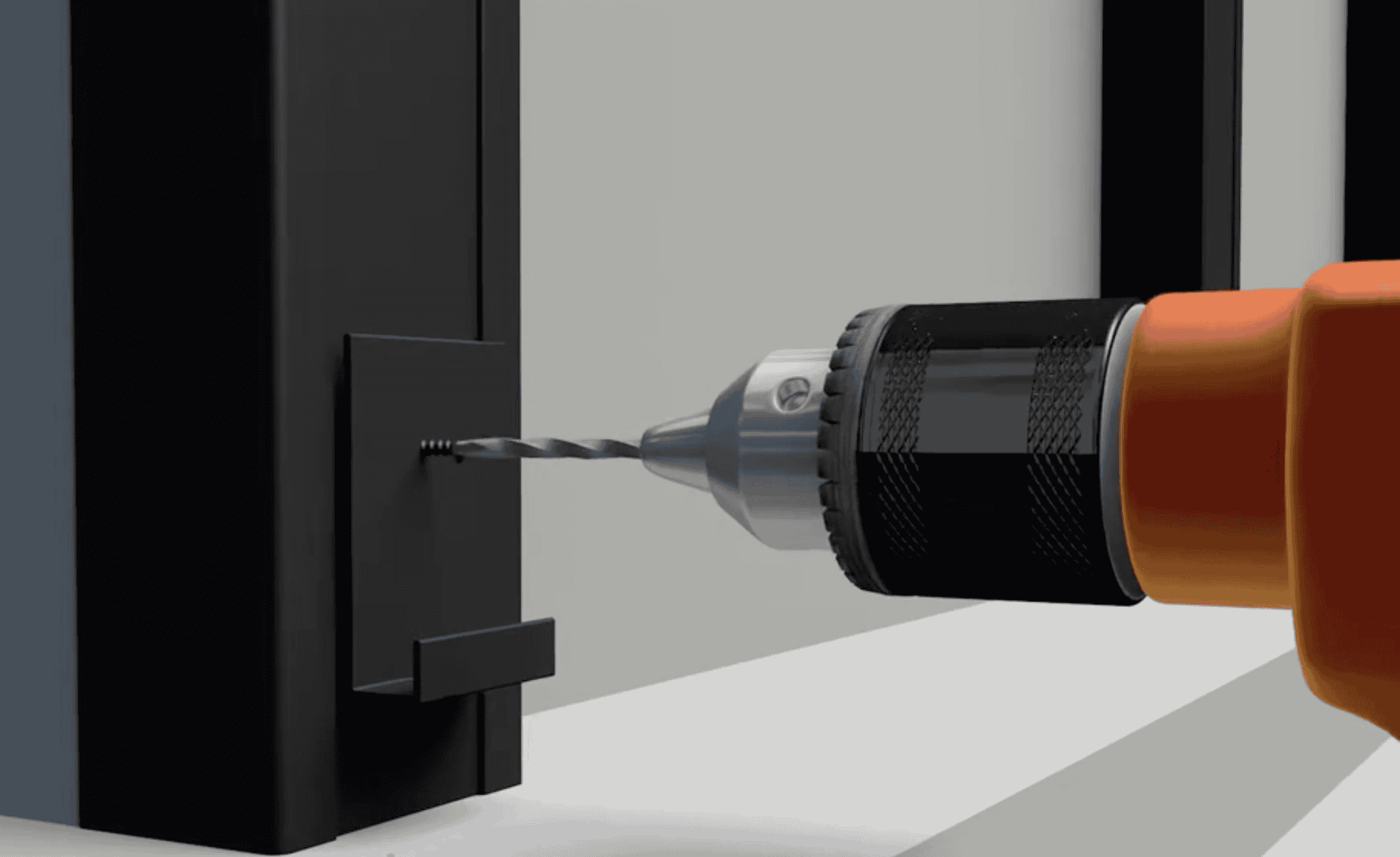

– Fix the battens securely to the wall using appropriate screws or anchors.

-

Attach Starter clips:

– Install a starter clips or base rail at the bottom of the wall to secure the first cladding panel.

– Ensure it is level, as this will determine the alignment of all subsequent panels.

-

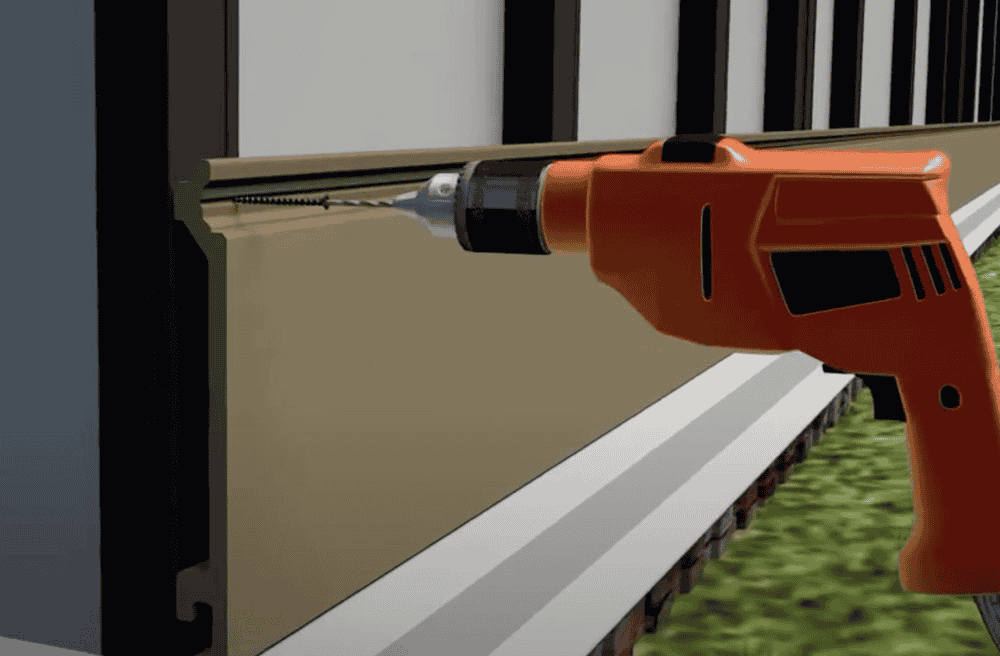

Install WPC Cladding Panels:

– Start with the bottom panel:

– Insert the first panel into the starter trim, ensuring it is securely seated.

– Use hidden fasteners or screws through pre-drilled holes, as per the manufacturer’s instructions.

– Add subsequent panels:

– Align the next panel above the previous one, locking them into place using the interlocking grooves (if applicable).

– Fix each panel to the sub-frame using screws.

– Check alignment frequently:

– Use a spirit level to ensure the panels remain straight as you work your way up the wall.

-

Install Trims and Edges:

– Use corner trims, edge trims to finish edges and corners neatly.

– Secure trims using screws or adhesives as recommended.

-

Allow for Expansion and Contraction:

– Leave small gaps (2-9 mm) between panels and trims to account for thermal expansion and contraction of the WPC material.

-

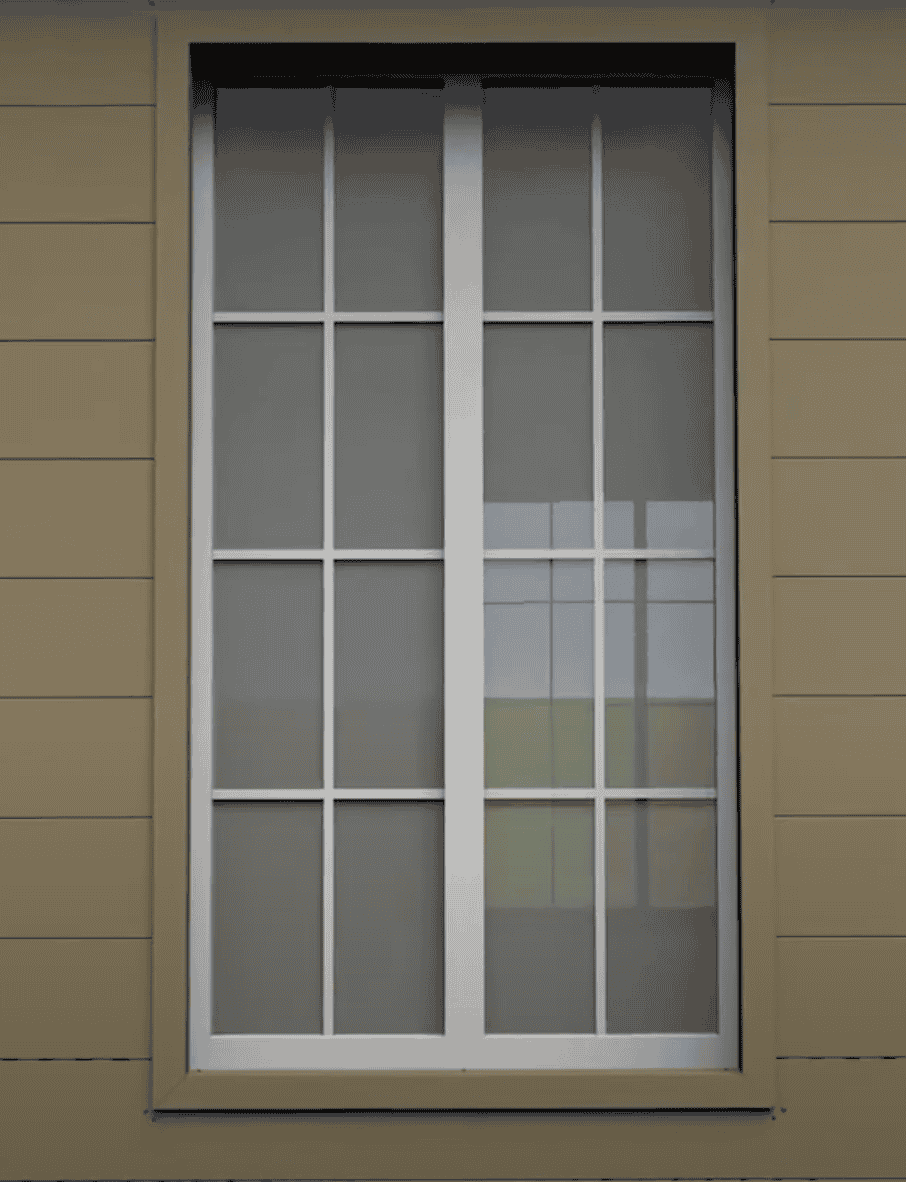

Final Inspection:

– Double-check the alignment and ensure all panels are securely fixed.

– Wipe down the cladding to remove dust or fingerprints.

Tips for a Professional Finish:

– Follow manufacturer instructions: Each WPC product may have specific installation requirements.

– Plan for drainage: Ensure water can run off freely to avoid pooling behind the cladding.

– Work methodically: Take your time to measure and cut panels precisely to avoid mistakes.

– Safety first: Wear appropriate protective gear when cutting or drilling.

With proper installation, WPC cladding will provides a durable, weather-resistant, and attractive finish to your building.