With the increasing global environmental awareness, the concept of green buildings is gradually deeply rooted in people’s hearts. Green buildings not only pursue aesthetics and practicality, but also emphasize minimizing negative impacts on the environment throughout the entire life cycle of the building, and creating healthy and comfortable living spaces for people. In this process, wood plastic composite materials, as a new type of environmentally friendly building materials, are increasingly receiving people’s attention.

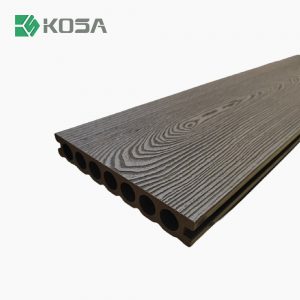

Wood plastic composites (WPC) material are a new type of composite material that has flourished both domestically and internationally in recent years. It mainly uses plastics such as polyethylene, polypropylene, and polyvinyl chloride to mix with more than 50% of waste plant fibers such as wood powder, rice husks, and straw to form new wooden materials. Then, through plastic processing processes such as extrusion, molding, and injection molding, it produces boards or profiles. This material is not only lightweight, easy to transport and install, reducing transportation and installation costs, but also does not use any harmful chemical additives during the production process, which is harmless to human health.

In green buildings, the application of wood plastic composite materials has many advantages. Firstly, it has high tensile, compressive, and impact strength, which can meet the requirements of building structures. Secondly, it can be completely biodegradable and will not cause long-term pollution to the environment, meeting the requirements of green buildings. In addition, wood plastic composite materials also have excellent insulation, heat insulation, sound insulation and other properties, which can improve the comfort and health of buildings, and create a more livable living environment for people.

In practical applications, wood plastic composite materials are mainly used in industries such as building materials, furniture, and logistics packaging. For example, in the field of construction, wood plastic composite materials can replace traditional wood or metal materials to make components such as doors and windows, floors, and wall panels. They not only have excellent physical properties, but also can reduce energy consumption and environmental pollution. In the furniture industry, wood plastic composite materials can be used to produce furniture products with beautiful and durable appearances, meeting people’s dual needs for environmental protection and aesthetics.

Meanwhile, the processing performance of wood plastic composite materials is also excellent. Due to its inclusion of plastics and fibers, it has processing properties similar to wood, and can be sawn, nailed, and planed using woodworking tools. Its mechanical performance is better than that of wooden materials, with a nail grip force generally three times that of wood and five times that of particleboard. In addition, the surface hardness of wood plastic composite materials is generally 2-5 times that of wood, which makes them more durable and stable in construction applications.

However, although the application of wood plastic composite materials in green buildings has many advantages, we also need to face some of its challenges. For example, the production cost of wood plastic materials is relatively high, which to some extent limits their widespread application in green buildings. In addition, there is currently no mature solution for the recycling and treatment of wood plastic materials, which needs to be addressed in future research.

Overall, the application of wood plastic composite materials in green buildings has broad prospects and potential. With the continuous progress of technology and the continuous improvement of environmental awareness, we have reason to believe that wood plastic composite materials will play a more important role in future green buildings, making greater contributions to building a more green, environmentally friendly, and beautiful building environment. At the same time, we also need to constantly explore and research, overcome its existing challenges, and promote its widespread application in green buildings.