In the selection of outdoor flooring materials, Co-extrusion decking and Timber decking are two common options. However, after in-depth research and practical application, Co-extrusion decking has shown significant advantages in many aspects.

First of all, in terms of material durability, Co-extrusion decking has excellent performance. The advanced Co-extrusion technology it adopts enables the floor to better resist erosion and wear from the external environment. In contrast, although timber decking also has certain anti-corrosion capabilities, its durability is often not as good as Co-extrusion decking during long-term use.

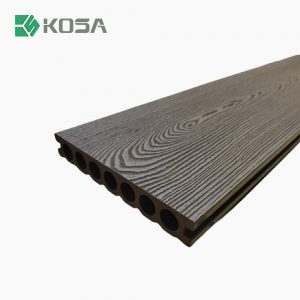

Secondly, in terms of appearance, Co-extrusion decking has more natural and beautiful characteristics. It can simulate a variety of wood grains and colors, providing more abundant choices and satisfying the pursuit of beauty by different consumers. Timber decking is relatively simple in appearance, and it is difficult to achieve the diversity and realistic effect of Co-extrusion decking.

Furthermore, Co-extrusion decking is also easier to maintain. The special treatment of its surface makes it difficult for stains to adhere, and cleaning work is easy and convenient. Timber decking may require more frequent and complex maintenance measures to keep it in good condition.

In addition, Co-extrusion decking also performs well in environmental protection performance. It is usually made of recyclable materials, has low energy consumption during the production process, and has less impact on the environment. In contrast, the production and treatment of some Timber wood decking may cause certain pressure on the environment.