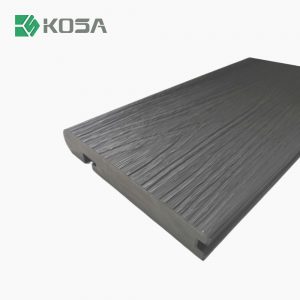

Co-extrusion decking is revolutionizing the composite decking industry with its advanced dual-layer technology. By fusing a high-performance polymer protective cover to a recycled composite core, this decking offers unmatched durability against fading, scratches, and moisture damage. Ideal for both residential decks and commercial spaces, co-extrusion decking combines the natural beauty of wood grain textures with cutting-edge protection.

The protective cover refers to the outer layer wrapped around the composite decking core, typically made of high-performance polymers. This layer offers excellent UV protection, resistance to scratches, and improved durability, keeping your decking surface looking pristine even after years of use. It helps prevent fading, stains, and surface wear, significantly extending the lifespan of your deck.

The core material of co-extrusion decking is made from Kosa composite materials, consisting of recycled plastic granules and wood fibers. This eco-friendly core provides strength, flexibility, and superior water resistance, making co-extrusion decking a reliable and sustainable choice for your outdoor projects.

Residential Patios: Enhance and enrich your outdoor living space with a beautiful, low-maintenance, long-lasting decking.

Commercial Spaces: Ideal for high-traffic areas that require durability and aesthetics.

Poolside Areas: Excellent water resistance makes it a perfect choice for areas around pools and spas and beachfront areas.

| Traditional WPC Decking | Co-extrusion Decking | |

|---|---|---|

| Traditional WPC Decking may experience fading, discoloration, and other issues in appearance after a period of use, especially when exposed to sunlight, rain, and other environments for a long time. Its weather resistance has certain limitations. Although it can resist the erosion of some natural factors, its appearance and performance will gradually deteriorate over time. | Co-extrusion Decking has significant advantages in weather resistance. It has a special co extrusion layer on its surface, which can effectively block the damage of ultraviolet rays and greatly reduce the fading phenomenon caused by sunlight exposure. At the same time, it also has better resistance to rain, moisture, and other factors, which can maintain the bright color and good texture of the appearance for a long time, making the outdoor decking always look new, greatly improving the aesthetics and overall decorative effect of the outdoor space. |

|

| The wear resistance of Traditional WPC Decking is relatively limited. In daily situations such as pedestrian walking and furniture movement, scratches and other wear phenomena may gradually appear, which will affect its service life and appearance quality. | Due to its unique co extrusion structure, Co-extrusion Decking has higher surface hardness and stronger wear resistance. The Co-extruded layer can effectively protect the main body of the board, making it more capable of withstanding various external friction forces. This means that it is less prone to wear and tear during long-term use, and its service life can be significantly extended. Compared to traditional plastic wood panels, Co-extrusion Decking can save users the cost of replacement and maintenance, making it a more economical and durable choice. |

|

| Traditional WPC Decking may require tedious steps during cleaning, and some common stains may be difficult to completely remove, especially after wear and tear on the surface of the board, making it easier for stains to penetrate and further increasing the difficulty of cleaning. | The surface co extrusion layer of Co-extrusion Decking is relatively smooth and less prone to stains, making it easier to clean. Even if there are stains attached, they are very easy to clean off, just use ordinary cleaning tools and cleaning agents to keep the floor clean and tidy. In terms of maintenance, it does not require frequent maintenance like traditional plastic wood panels, which can save users a lot of time and energy. |

|

| Co-extrusion Decking is currently the most advantageous outdoor decking material compared to traditional WPC Decking in terms of appearance and weather resistance, wear resistance and service life, as well as cleaning and maintenance convenience. | ||

1. When placing the joists, leave a distance of 3-5 mm from the building.

2.The joist needs to pre-drilling before fixing the expansion bolts.

3. The spacing between joists should be 25-30cm.

4. The spacing between expansion bolts should be 30cm to 40cm.

5. After the joist is fixed, drainage should be done to avoid factors that damage the composite decking, such as water swelling.

6. Fix the starter clips on one side of the joist.

7. Insert the composite decking into the starter clips, and install the first composite decking board.

8. Insert the clips in composite board and screw into joist (do not tighten)

9. Insert the second board into previous clips

10. Insert next row of clips securing composite board (do not tighten)

11. Fully tighten clips & screws and repeat

12. Finish the corner edging and complete the composite decking installation.

Kosa’s Co-extrusion decking project case fully demonstrates the beauty and practicality of Co-extrusion decking, and provides a high-quality solution for the creation of outdoor space. The Co-extrusion decking has a clear and natural texture, warm and comfortable colors, and perfectly integrates natural and modern elements. It not only retains the texture and beauty of wood, but also has excellent properties such as waterproof, moisture-proof, and wear-resistant, making the space both beautiful and practical.

Address: No.6, Baota Road, Economic Development Zone, Hefei City, Anhui Province, China

Email: sales@kosadeck.com

Mob/WhatsApp: +86 189 1758 9785

As a leading manufacturer of wood plastic composite (WPC) products in China, Kosa is committed to providing innovative and environmentally friendly solutions for the construction and home industry, we always providing customers with the superior quality WPC products with the most competitive prices.