When selecting the right decking material for your project, it’s crucial to weigh your options carefully. Two popular choices, WPC decking (Wood-Plastic Composite) and FRP decking (Fiber Reinforced Polymer), stand out for their unique benefits and applications. Both materials offer durability and low maintenance, but they differ significantly in terms of strength, appearance, cost, and performance in various environments. Understanding the distinctions between WPC and FRP decking will help you make an informed decision for your next project, whether it’s residential or industrial.

What Is WPC Decking?

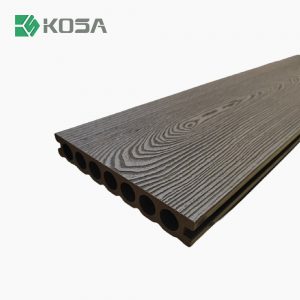

WPC Decking is a composite material made from wood fibers and plastic, typically either recycled polyethylene or PVC. This hybrid material is designed to capture the aesthetic appeal of natural wood while incorporating the durability and moisture resistance of plastic. WPC decking is popular for outdoor residential spaces like patios, garden decks, and balconies because it mimics the warm, organic look of wood while offering enhanced resistance to decay, mold, and termites.

What Is FRP Decking?

FRP Decking, on the other hand, is a high-performance composite made from fiber-reinforced polymer, where fibers like glass or carbon are embedded in a polymer matrix, typically vinyl ester or polyester. This material is incredibly strong and lightweight, designed for extreme durability in industrial, commercial, and infrastructure applications. FRP decking is commonly used in environments exposed to high stress, moisture, or chemicals—such as bridges, docks, water treatment plants, and industrial walkways.

Key Differences Between WPC Decking and FRP Decking

| Feature | WPC Decking | FRP Decking |

|---|---|---|

| Material Composition | Wood fibers + plastic (recycled materials often) | Polymer matrix reinforced with glass or carbon fibers |

| Aesthetic Appearance | Natural wood-like appearance with multiple color and grain options | More industrial appearance, available in various colors but lacks wood-like texture |

| Strength & Durability | Moderate durability; suitable for residential use | Extremely strong and durable, suitable for industrial applications |

| Moisture Resistance | Good moisture resistance, but can swell if wood fibers are exposed | Completely impervious to water; ideal for marine and wet environments |

| Maintenance | Low maintenance, requires occasional cleaning | Maintenance-free; highly resistant to wear and corrosion |

| Weight | Heavier than natural wood, but manageable | Lightweight but stronger than WPC, easier to handle in some cases |

| Environmental Impact | Often made with recycled materials; eco-friendly | Not biodegradable, made from synthetic materials |

| Cost | More affordable, great value for residential and light commercial use | More expensive upfront due to advanced materials |

| UV & Fade Resistance | Improved UV stability; can fade slightly over time | Excellent UV resistance, with minimal fading over long periods |

| Installation Ease | Easy to cut and install, similar to wood | Requires specialized tools for cutting, but lightweight and easy to handle |

| Applications | Best for residential decks, patios, balconies, boardwalks | Ideal for industrial walkways, bridges, docks, and heavy-duty infrastructure |

1. Material Composition

WPC Decking: A blend of wood fibers and plastic. Its wood-like appearance makes it ideal for aesthetic outdoor spaces.

FRP Decking: Composed of polymer reinforced with glass or carbon fibers. Known for its industrial-grade strength and resistance to environmental stress.

2. Strength and Durability

WPC Decking: While durable compared to natural wood, WPC is susceptible to scratches, dents, and some warping in extreme heat. It is best suited for light to moderate use, primarily in residential or commercial outdoor settings.

FRP Decking: Extremely strong and resilient, FRP can withstand heavy loads and impact, making it ideal for industrial and marine applications. It doesn’t warp, crack, or degrade, even in harsh environments, and far outperforms WPC in terms of longevity.

3. Moisture Resistance

WPC Decking: Offers moderate moisture resistance, but the wood fibers in the composite can still absorb water over time if exposed, potentially leading to swelling or mold growth in extreme conditions.

FRP Decking: Completely impervious to water and moisture, making it perfect for high-moisture environments like docks, marinas, or waterfront structures. FRP will not swell, rot, or mold, regardless of exposure.

4. Maintenance Requirements

WPC Decking: Requires periodic cleaning to remove dirt, mildew, and potential stains. While much lower maintenance than natural wood, WPC may fade or stain over time when exposed to sunlight or harsh weather.

FRP Decking: Essentially maintenance-free. It doesn’t corrode, warp, or degrade, making it a long-term solution with virtually no upkeep. This makes FRP ideal for structures where minimal maintenance is a priority.

5. Aesthetic Appearance

WPC Decking: Known for its wood-like appearance, WPC offers a natural, rustic look with a range of colors and grain patterns. Over time, some fading may occur, but modern versions are more UV-resistant.

FRP Decking: Generally has a more utilitarian, industrial look, though it can come in different colors and textures. It lacks the natural appeal of wood but offers slip-resistant surfaces, ideal for safety in high-traffic or wet areas.

6. Environmental Impact

WPC Decking: Often produced using recycled plastics and wood by-products, making it a relatively eco-friendly option. However, it is not biodegradable, so disposal at the end of its life cycle can be a concern.

FRP Decking: Manufactured from synthetic, non-recycled materials. While it is not biodegradable or easy to recycle, FRP’s long lifespan and lack of maintenance make it a sustainable option over the long term in demanding environments.

7. Cost

WPC Decking: More affordable, making it a popular choice for homeowners and small commercial projects. It provides a good balance of aesthetics, durability, and cost.

FRP Decking: More expensive upfront due to the advanced materials and manufacturing process. However, its long-term durability and low maintenance can result in lower overall lifecycle costs, especially in industrial or high-performance settings.

Applications of WPC Decking and FRP Decking

WPC Decking Applications

– Residential patios and garden decks

– Balconies and terraces

– Walkways in parks and outdoor recreational areas

– Boardwalks and light commercial spaces

WPC is best suited for areas where appearance and moderate durability are priorities. It’s an ideal option for homeowners who want the look of wood without the constant upkeep.

FRP Decking Applications

– Industrial walkways and platforms

– Bridges and infrastructure projects

– Docks, marinas, and waterfront structures

– Water treatment plants and chemical facilities

FRP is the go-to choice for environments that demand high strength, resistance to moisture, chemicals, and heavy loads. Its industrial-grade performance makes it ideal for demanding applications where longevity and resilience are paramount.

Conclusion: Which Should You Choose?

The choice between *WPC decking* and *FRP decking* depends largely on your specific project needs.

– If you’re working on a residential project or need a solution that mimics the look of natural wood, WPC decking is likely your best bet. It offers good durability, low maintenance, and a more affordable price point, all while delivering an attractive, natural appearance.

– If your project involves industrial or high-performance requirements, where strength, moisture resistance, and long-term durability are crucial, FRP decking is the superior option. Although it comes with a higher upfront cost, its long lifespan and minimal maintenance make it cost-effective in the long run.

Both materials have their advantages, and choosing the right one ultimately depends on balancing aesthetics, performance, and cost according to the demands of your environment.